We are innovative in what we bring to the commercial metal roof and wall industry. Our patented designs are engineered to meet, exceed, and maximize each client’s requirements through smarter and more resilient manufacturing and construction disciplines.

The chart above shows forces that are based on the building’s height, geographic location, its exposure (on open water with no obstructions), panel width, and infrastructure spacing. The pounds per sq. inch are forces for a given wind speed exerted on each roof panel’s connection based on the connection’s location across the roof.

The yellow area identifies the limits of conventional attachment methods. Zone 3 is located at all corners of the building and measures 10’ x 10’. Zone 2 is the remaining perimeter of the building with a 10’ width from the edge of the building. Zone 1 is the remaining portion of the roof not covered by zone 3 and zone 2.

The Tandem® Series Roof/Wall System™ is shown next in blue. It is designed to withstand these forces. Conventional systems cannot achieve 130mph wind force protection without additional infrastructure being added to Zone 3 and Zone 2. With additional infrastructure, conventional systems cannot withstand forces higher than those at 185mph. If conventional systems suffer debris impacts, their structural abilities can decrease significantly.

Tandem Building Products™’ roofs are engineered for 360º movement of the roof plane to accommodate expansion and contraction. In a conventional through-fastened metal roof, panels are screwed down to the infrastructure, creating resistance on every screw due to thermal movement. In conventional standing seam metal roofs, clips only account for longitudinal expansion and contraction.

TBP™’s panels are anchored to our clip system which slides freely in all directions. Panels are free to move without resistance because they are not screwed down, they are anchored to our clip system that can adjust 360º as the metal grows from heat or shrinks from cold.

As seen in the video above, the Tandem® 360º Clip™ is not limited in the direction of expansion and contraction. This unrestricted movement of the roof system means there are no stresses exerted on the panel or its attachments. The no-stress movement allows the panels to last 2x-5x longer than conventional building systems.

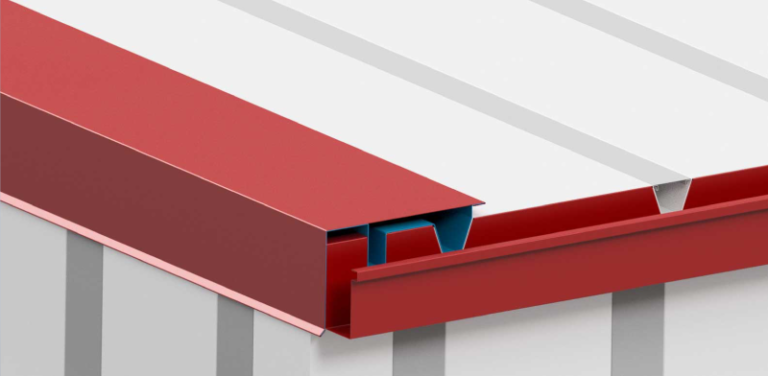

Tandem® Flashing™ has the same wind rating as the roof/wall system and utilizes the same attachment methods for 360-degree movement. The system’s flashing meets the same high wind rating as the structure. Conventional roof/wall flashings are not rated for high winds and are the first element to fail during a hurricane or tornado, thus initiating a domino effect of failure throughout the building envelope.

The patented Tandem® 300™ design can be engineered to any wind-speed requirement while maintaining impact resistance. Conventional metal roof/wall systems fail in high winds that are mixed with large amounts of windborne debris. TBP™’s 22-gauge panels not only withstand the highest tornado wind speeds, but they also provide substantial resistance against impact damage because debris and hail cannot structurally damage the inverted ribs.

Conventional 150-185 mph roof systems cannot be unsealed to replace a single panel because the panels are mechanically seamed together. Tandem®’s panel design offers a “panel replacement” solution versus the post-catastrophe costly and time-consuming “rip and replace” of an entire roof requirement of a traditional roof. Individual panels can be replaced if field repairs cannot correct the damage. With the Tandem® 300™, single or multiple panels can be removed and replaced to bring the roof back to its original wind rating.

The elimination of ponding water is critical in low-slope applications. The Tandem® Inverted Panel™ is unique to the marketplace in that the inverted ribs become water channels funneling water off the roof system. Water is intentionally directed to channel into the inverted ribs and flow to the gutters. While most of the water will shear off the large surface area of the roof, the inverted ribs can siphon any remaining water into these channels and eliminate almost all water pooling on the roof.

With the Tandem® Series™ design, insulation and fire-rated boards do not have to be mechanically fastened in place. TBP™ infrastructure designs allow for rigid insulation like Polyisocyanurate (ISO) to be used with the Tandem® Roof/Wall System™ providing uniform insulation layers. This design allows for insulation values exceeding R-100.

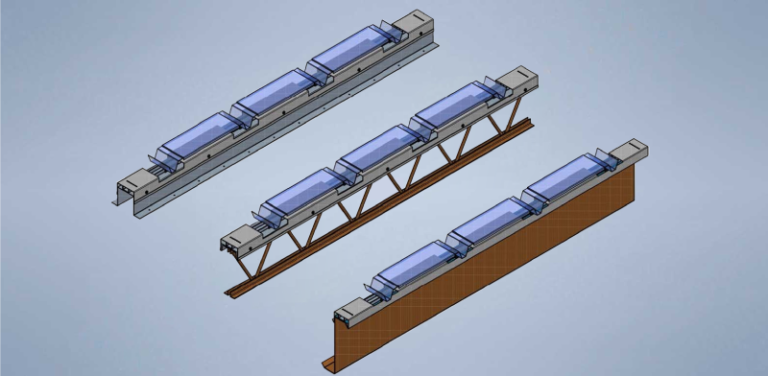

The Tandem® 360º Clip™ can be installed on any style or size of structural member including Z & C purlins/girts, hat channels, steel web joists, and tubular beams with shear resistance being the common factor among all mechanical fasteners. The fasteners tie the clip to the structural member in such a way that shearing forces would be required to dislodge the clip.

When the Tandem® U-Beam™ is combined with the Tandem®300 Roof/Wall System™, the entire building can withstand forces of 300mph. The Tandem® U-Beam™ is an infrastructure component and can be configured to house lighting, electrical power, and fire suppression systems. Smart technology (including bluetooth connection points, WiFi access points, IR sensors, HVAC controls, security cameras and more) can be configured within the Tandem® U-Beam™. By integrating these components during the manufacturing process, significant time and cost savings are realized when compared to conventional systems.